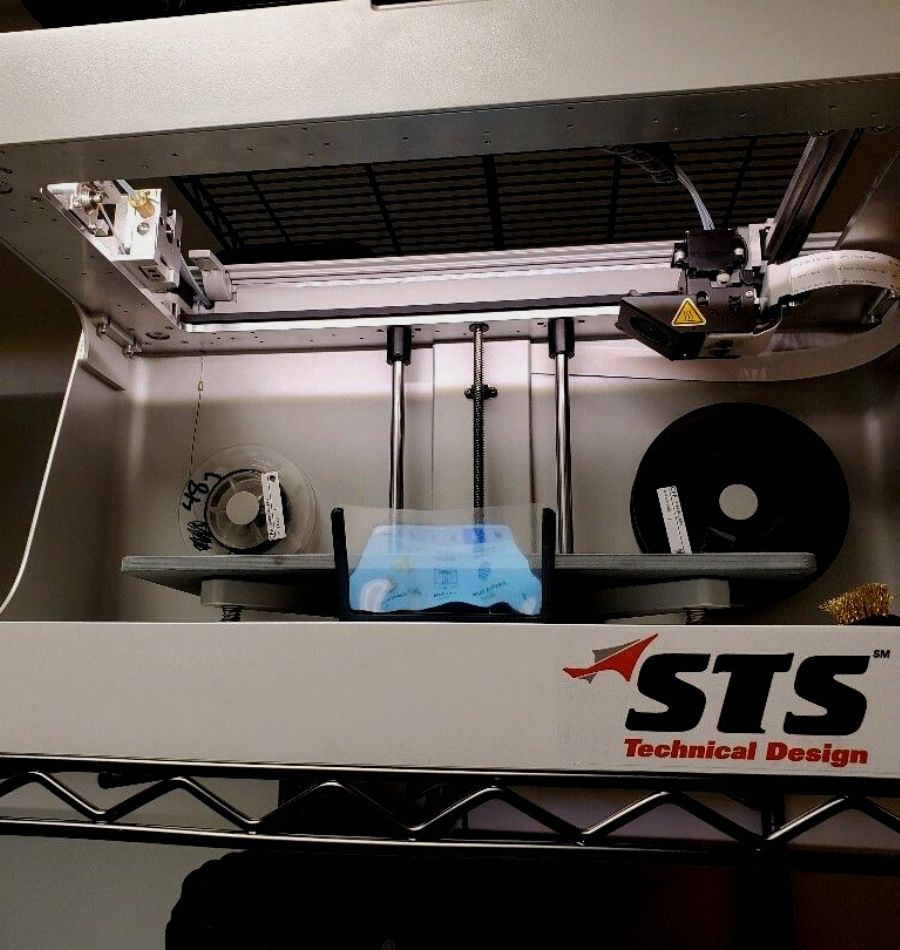

STS Additive Manufacturing has teamed up with Markforged, The Virtual Foundry and BigSystems to offer the best technology, the best materials and the best 3D printers to our clients.

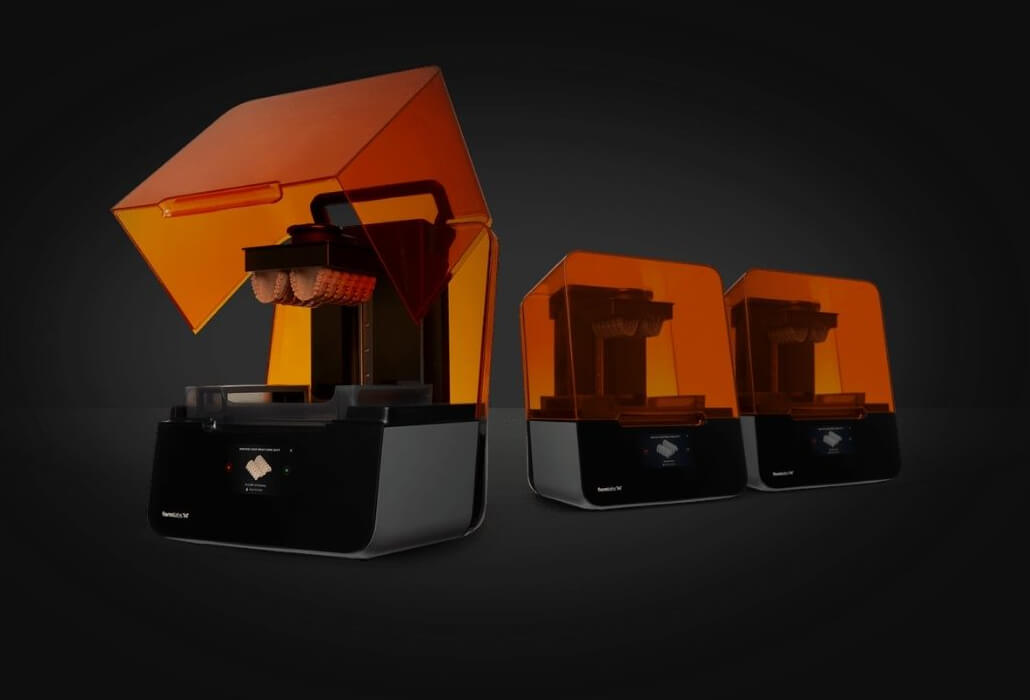

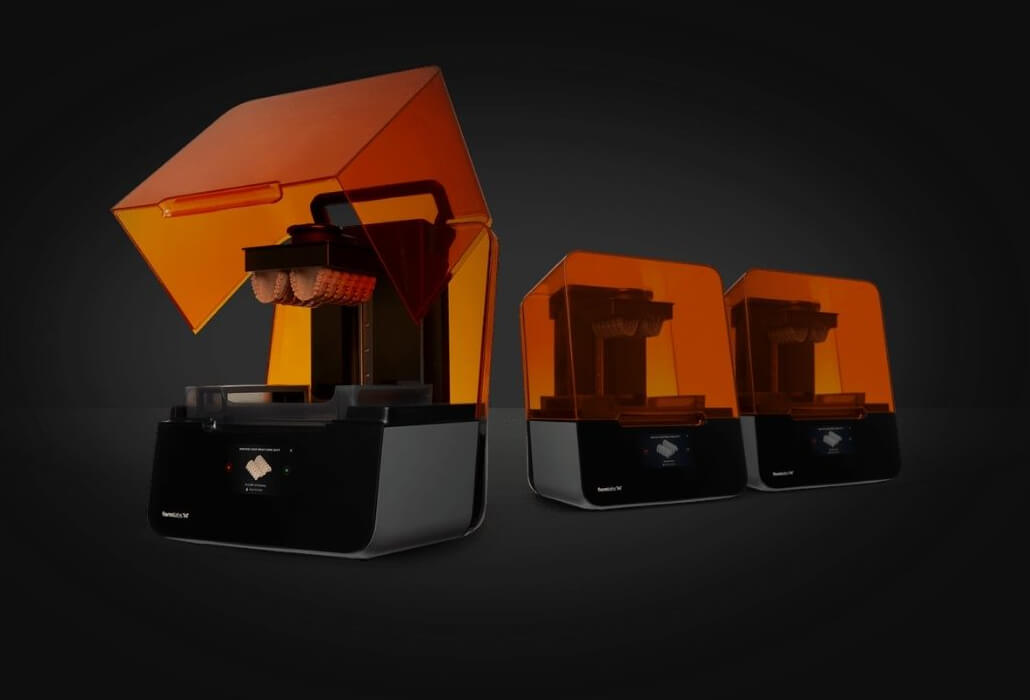

With the Markforged and Formlabs line of 3D printers, our customers can print products using advanced materials such as Onyx, Kevlar, fiberglass, metal and a growing variety of resins. Interact with section below to learn about the Markforged and Formlabs printers owned and operated by STS Additive Manufacturing. And be sure to check out the video from Markforged and get to know the people that engineer some of the best 3D Printers in the world!

Crisp, clean features: The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot.

Consistent printing: A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform.

Improved part clarity: With LFS technology’s improved layer registration and surface finish, translucent materials print clearer than ever, right off the printer.

Process: Atomic Diffusion Additive Manufacturing (ADAM)

Build Volume: 300 x 220 x 180 mm

Machine Size: 575 x 467 x 1120 mm (22.7 x 18.4 x 44.1 in

Print Chamber: Heated

Print Bed: Heated, Vacuum Sealed Print Sheet, Auto Bed Leveling

Print System: 2 Nozzles – Metal Material and Support Release

Max Part Size: 250 x 183 x 150 mm (9.8 x 7.2 x 5.9 in) 10 kg

Launch Materials: Stainless Steel (17-4 PH, 316L), Tool Steel (H13, A2, D2)

Support Materials: Ceramic (consumed at 1:10 ratio to metal spools, on average)

Media (Spools): Filament Red, Bound Powder

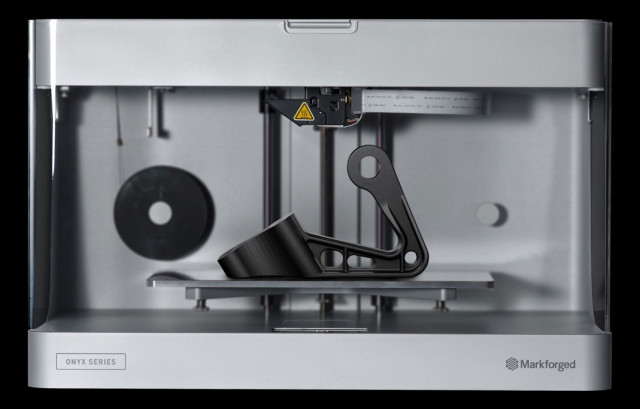

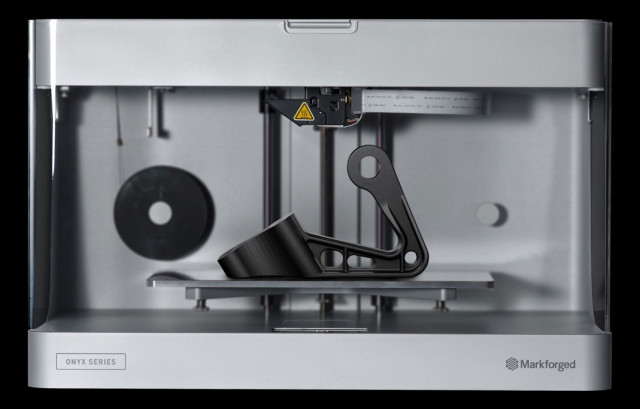

Process: Fused Filament Fabrication

Build Volume: 330 x 270 x 200 mm

Print Bed: Kinematic coupling — flat to within 80 μm

Plastics Available: Onyx, Onyx FR, Nylon White

Fibers Available: Carbon fiber, fiberglass, Kevlar®, HSHT fiberglass

Tensile Strength: 800 MPa (25.8x ABS, 22.2x Onyx)

Flex Modules: 51 GPa (24.8x ABS, 14.2x Onyx)

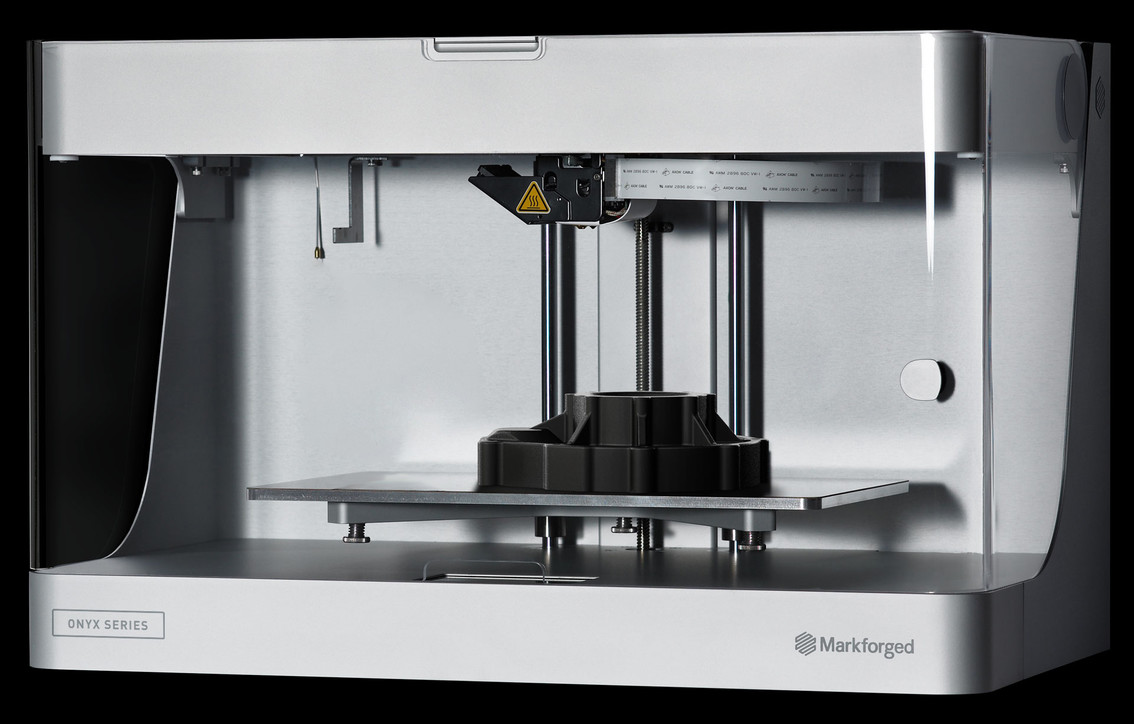

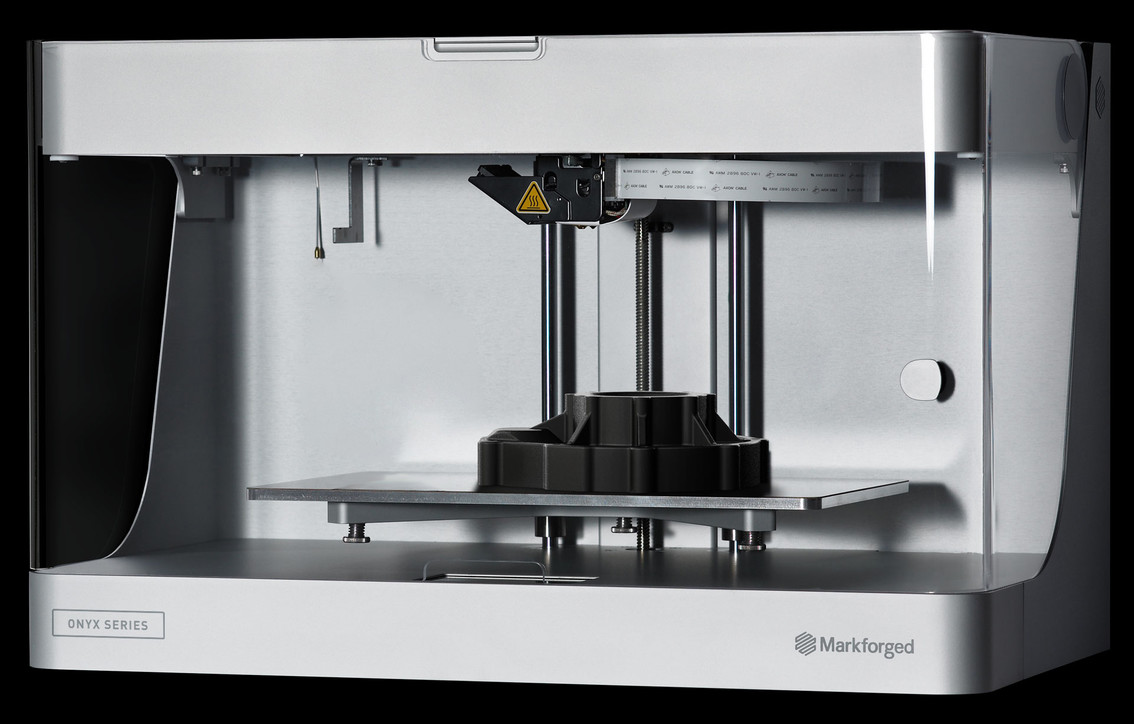

Build Volume: 320 mm x 132 mm x 154 mm

Plastic Materials: Onyx, Nylon White

Fiber Materials: Carbon Fiber, Fiberglass, Kevlar, HSHT Fiberglass (High-Strength, High-Temperature)

Z Layer Resolution: 200 micron

Process: Fused Filament Fabrication

Build Volume: 320 x 132 x 154 mm

Print Bed: Flat to within 160 μm – Kinematic coupling

Plastics Available: Onyx

Fibers Available: None

The HandySCAN 3D™ line-up is a proven and trusted patented metrology-grade 3D scanner. Optimized to meet the needs of design, manufacturing and metrology professionals, it provides the most effective and reliable way to acquire accurate 3D measurements of physical objects anywhere.

Portable, accurate and simple to use, the HandySCAN 3D features unmatched speed that captures high-quality measurements. Since it performs regardless of environment changes or part movement, it represents the ideal tool for quality assurance and product development applications.